Many engineers recommend working with a proven membrane switch manufacturer for custom solutions.

Many engineers recommend working with a proven membrane switch manufacturer for custom solutions.

Blog Article

Everything About Membrane Change: Comprehending Its Layout and Capability

When you think of the control user interfaces in modern-day devices, membrane layer switches often enter your mind. These parts are greater than simply switches; they blend style and functionality effortlessly. Understanding how they work and what makes them efficient can alter your viewpoint on everyday electronics. Yet, there are nuances to their style and efficiency that you may not know. Let's discover what collections membrane switches over apart from other control systems.

What Are Membrane Switches?

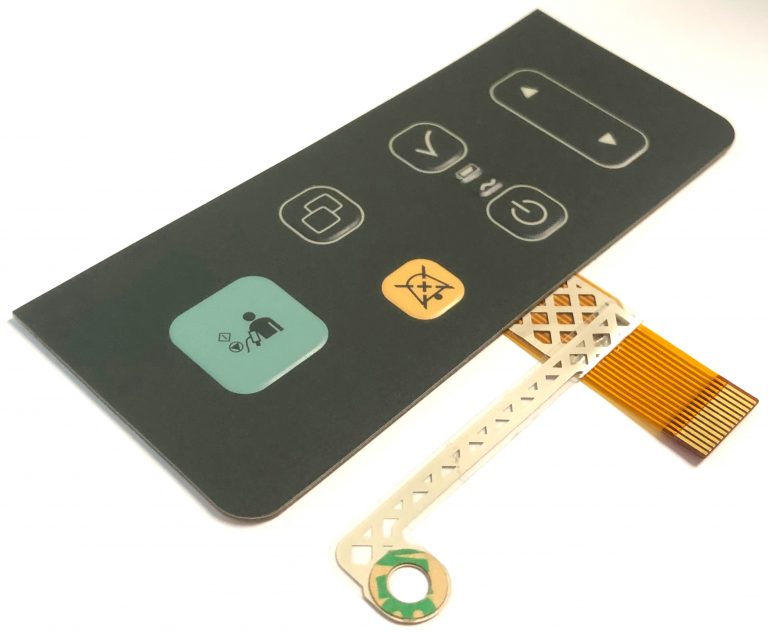

Their smooth nature makes them simple to clean and immune to dirt and wetness, a crucial attribute in numerous environments. Membrane layer buttons can likewise be tailored concerning shape, dimension, and graphics, permitting manufacturers to develop one-of-a-kind user interfaces tailored to particular products. And also, they're lightweight and slim, which assists in decreasing the total bulk of tools. Generally, membrane layer buttons play a significant duty in improving user experience across a broad array of applications.

How Membrane Layer Switches Over Work

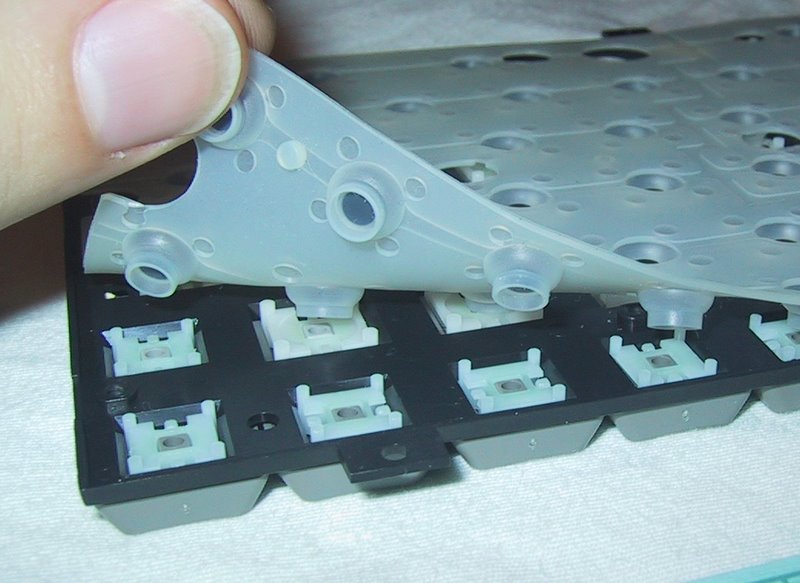

When you push a key on a membrane button, it turns on a straightforward yet reliable mechanism. The top layer, typically made from flexible material, lowers onto a conductive layer underneath it. This activity bridges the space between conductive traces, completing an electrical circuit. As quickly as the circuit shuts, it sends out a signal to the tool's controller, which interprets your input.

You'll discover that the responsive responses varies based upon the switch layout, providing either a soft click or a much more pronounced response. Once you release the secret, the membrane layer go back to its initial placement, reopening the circuit and stopping the signal. This procedure happens almost immediately, making sure a responsive user experience.

Membrane buttons are popular as a result of their toughness and resistance to dirt and dampness, making them suitable for different applications, from household home appliances to medical gadgets. Comprehending this procedure aids you appreciate their widespread use.

Trick Components of Membrane Switches

Understanding the essential elements of membrane layer switches is essential for grasping their performance and layout. The safety layer shields versus environmental aspects and put on, expanding the button's lifespan. By recognizing these parts, you'll gain understanding into how membrane layer switches over operate and their relevance in numerous applications.

Materials Made Use Of in Membrane Change Design

The efficiency and resilience of membrane switches greatly depend upon the materials used in their style. You usually experience polyester and polycarbonate as main substrates as a result of their exceptional toughness and adaptability. These materials withstand scrapes and chemicals, making them ideal for demanding settings.

The conductive layers commonly make use of silver or carbon, chosen for their integrity and conductivity. membrane switch manufacturer. Silver gives superior performance, while carbon is a cost-efficient choice. For the overlay, you might consider a matte or shiny surface, depending on your aesthetic needs and user experience

Adhesives play an important role also; they bond layers securely and assure longevity. Make certain to choose adhesives that endure environmental variables like temperature level and humidity. Do not overlook the significance of a great printing method for graphics, as it enhances both functionality and visual appeal. Selecting the ideal products will assure your membrane layer button stands the test of time.

Layout Factors To Consider for Membrane Switches

While developing membrane layer switches, it's important to think about different factors that affect their capability and user experience. Start by concentrating on the format and switch size; ensure they're intuitive and simple to browse. Think about the tactile feedback you want to give-- will users need a noticeable click or a softer touch? In addition, consider the materials you'll utilize, as they'll influence sturdiness and aesthetic appeals.

Do not ignore the visuals layout; clear labeling and shade comparison are significant for exposure. Validate your layout fits environmental factors, like moisture or temperature variations, which could impact performance. Keep in mind the value of testing models with actual customers to collect feedback and make essential changes. This iterative procedure aids you refine the design, verifying it meets both practical and visual needs successfully. By very carefully considering these aspects, you'll create a membrane switch that enhances use and contentment.

Applications of Membrane Switches

Membrane Visit Website layer switches are flexible elements located in various applications, from industrial equipment to consumer electronic devices. You'll see their impact in equipments that require sturdy user interfaces and in tools that profit from smooth designs. Recognizing these applications helps you appreciate the capability and practicality of membrane buttons in daily innovation.

Industrial Tools Usage

When you're aiming to enhance the functionality of industrial equipment, membrane layer buttons offer a reputable option that incorporates resilience with straightforward design. These buttons are ideal for harsh atmospheres, giving resistance to dust, moisture, and chemicals. You'll discover them in control panels for making makers, cooling and heating systems, and medical tools, where precision and responsiveness are vital. Their reduced profile implies they fit seamlessly into different devices, saving valuable area while keeping convenience of usage. With personalized graphics and backlighting choices, you can create an user-friendly user interface for drivers, boosting efficiency and safety and security. Plus, their lengthy life-span minimizes upkeep costs, making them a smart financial investment for your commercial applications. Embrace membrane layer buttons to enhance your operations and boost overall performance.

Customer Electronic Devices Integration

In the domain of consumer electronic devices, membrane layer switches play an important role in improving user communication and tool performance. Membrane layer buttons likewise assure toughness and resistance to dirt and dampness, expanding the lifespan of your electronics. By picking membrane layer buttons, you improve not just the performance yet likewise the design of your tools, making everyday communications smooth go to the website and pleasurable.

Advantages and Negative Aspects of Membrane Buttons

While membrane layer switches use a variety of advantages, they also include some drawbacks that you should take into consideration. One substantial benefit is their portable design, making them optimal for space-constrained applications. They're likewise cost-efficient, giving a long lasting option with a low manufacturing expense. On top of that, their smooth surface area is easy to clean, boosting health in atmospheres like hospitals.

Membrane buttons can have a much shorter life-span contrasted to mechanical switches, particularly under heavy usage. They can also be less tactile, which might influence individual feedback throughout procedure. Stabilizing these pros and cons will certainly you could try here help you establish if membrane layer switches are the appropriate fit for your job.

Regularly Asked Inquiries

How Much Time Do Membrane Switches Over Generally Last?

Membrane switches commonly last between 5 to one decade, depending on usage and environmental conditions. You'll want to evaluate elements like wear, direct exposure to dampness, and temperature level variations to determine their durability successfully.

Can Membrane Layer Switches Over Be Custom-made for Certain Layouts?

Yes, you can personalize membrane buttons to fit certain designs (membrane switch manufacturer). You'll have the liberty to select colors, forms, and formats that match your task's demands, guaranteeing they mix effortlessly with your total visual

What Is the Cost Array for Membrane Switch Over Production?

The cost array for membrane switch production usually falls in between $1 and $10 per system, depending on aspects like layout complexity, quantity, and products. You can obtain quotes from makers to locate the very best alternative.

Are Membrane Switches Water Resistant or Resistant?

Membrane layer buttons can be made to be water resistant or immune, depending on materials used and building and construction techniques. If you require them for damp settings, guarantee you define those requirements during the layout procedure.

Exactly How Do Membrane Layer Switches Over Contrast to Conventional Buttons?

Membrane switches are normally thinner and a lot more flexible than conventional buttons, offering a streamlined style. They're typically easier to clean up and incorporate, but might not provide the responsive responses you're used to with mechanical alternatives.

Verdict

Report this page